In the world of industrial automation, mechanical manufacturing, and process control, the emergency stop switch (E-Stop) is one of the most important safety components. When an unusual situation occurs, pressing the emergency stop switch immediately cuts off the power supply or control signals to prevent further damage and ensure the operator’s safety.

If you are looking for an emergency stop switch that combines safety, durability, and intelligent visibility, this article will guide you through the key design factors and explain why our latest model HBDS1-AGQ22F-11TSC stands out from the market.

1. Robust and safe: The new standard in aluminum alloy construction

In demanding industrial environments, structural integrity is synonymous with safety.

Traditional plastic emergency stop holders are often damaged or loosened by heat, vibration, or moisture. Our aluminum alloy emergency stop switch is designed to meet these challenges with:

- High-strength metal housing – Anodized aluminum housing for excellent impact and corrosion resistance;

- Sealed potting with bottom terminals – IP67 waterproof and dustproof protection, preventing internal oxidation and short circuits;

- Integrated LED lighting – Clear visual feedback of device status, ideal for dark or noisy environments;

- Modular design – Quick installation, easy maintenance, and multiple contact block configurations (NO/NC).

If your machines are operated outdoors, in factories, or under harsh conditions, this emergency stop switch provides the reliability and protection you need.

2. How to reset an emergency stop switch?

The method for resetting an emergency stop switch affects both safety and user-friendliness. Common reset mechanisms include:

- Twist-Release – Press and twist to unlock (the most common type).

- Pull to unlock – Suitable for larger panels or stations.

- Key release – Prevents unauthorized resetting, ideal for high-security systems.

Our emergency stop switch series products support both the Twist-Release type and key release type and can be integrated with LED indicator lights that synchronize with the operating status, providing clear and immediate confirmation of the reset status.

Not sure which version fits your equipment? Contact our engineers for personalized configuration advice.

3. Where are emergency stop switches required?

According to ISO 13850 and IEC 60204-1, emergency stop devices are mandatory in all areas where hazardous movements or manual interventions may occur, including:

- Automated production lines and robot cells;

- Packaging, printing, and cutting machines;

- Test benches and laboratory equipment;

- Elevators, conveyors, and transport systems;

- CNC machining centers and industrial robots.

Tip: Always install emergency stop buttons within the operator’s reach from all working positions – ideally within 0.5 seconds’ reach.

4. What are the five requirements for an emergency stop device?

A certified emergency stop device must meet five basic safety principles:

- High visibility – Red mushroom head with a yellow background for immediate detection;

- Direct operation – Operable without tools or software;

- Mechanical locking – Remains locked until manually reset;

- Independence – Functions mechanically, even in the event of control voltage failure;

- Reliability and tamper resistance – Withstands repeated use, vibrations, and harsh conditions.

Our metal emergency stop products are CE, RoHS, and ISO9001 certified and have passed rigorous salt spray, vibration, and endurance tests – to ensure consistent performance when it matters most.

5. Intelligent lighting and individual branding

Modern industrial systems are increasingly networked and visualized, and emergency stop systems are evolving with them.

Our illuminated intelligent emergency stop switch offers features such as:

- Status indication via LED lighting (e.g., Red = Stop, Green = Ready);

- PLC/IoT connectivity for real-time monitoring and event reporting;

- Customizable options – Engrave your logo, choose LED colors, cable length, or plug type.

A sophisticated, illuminated emergency stop switch is not just a safety feature – it is a visual statement of your brand’s quality and professionalism.

Recommended emergency stop switch products:

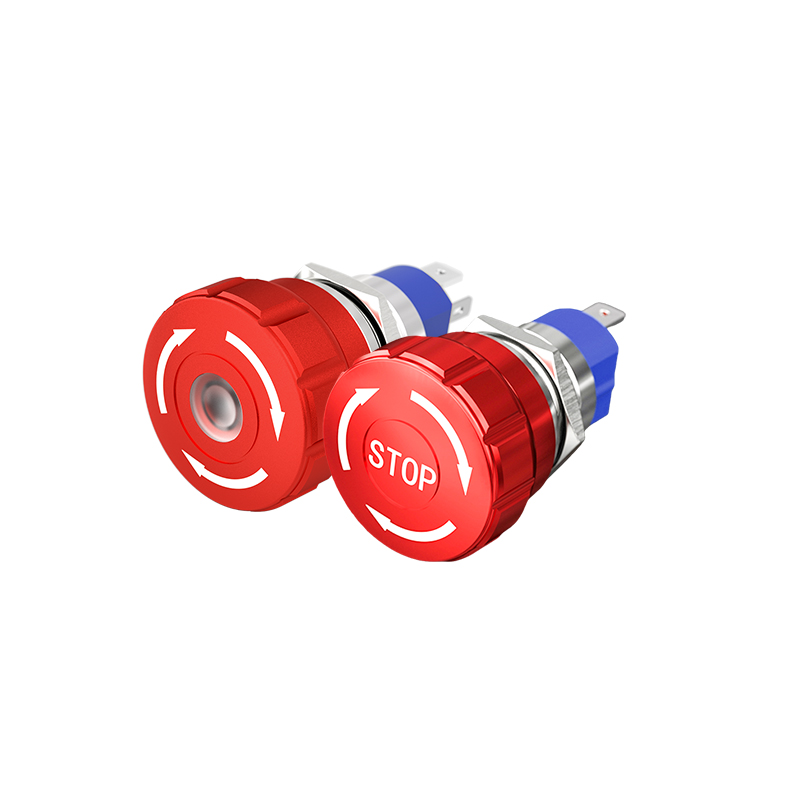

1. HBDS1-AGQ-TS Series

Features: IP67 waterproof, supports 1NO1NC/2NO2NC contact combinations, dual-color lighting available

2. HBDS1-D22C-TSC Series

Features: 10A high-current design, IP67 waterproof, thicker terminals provide more sensitive contact, dual-color lighting available

3. HBDS1-AGQ16H Series

Features: 5A current design, environmentally friendly plastic material, with a small head design, suitable for tight environments

4. HBDS1-AY Series

Features: Economical and affordable model with full functionality, 5A current environment, suitable for 16mm installation holes

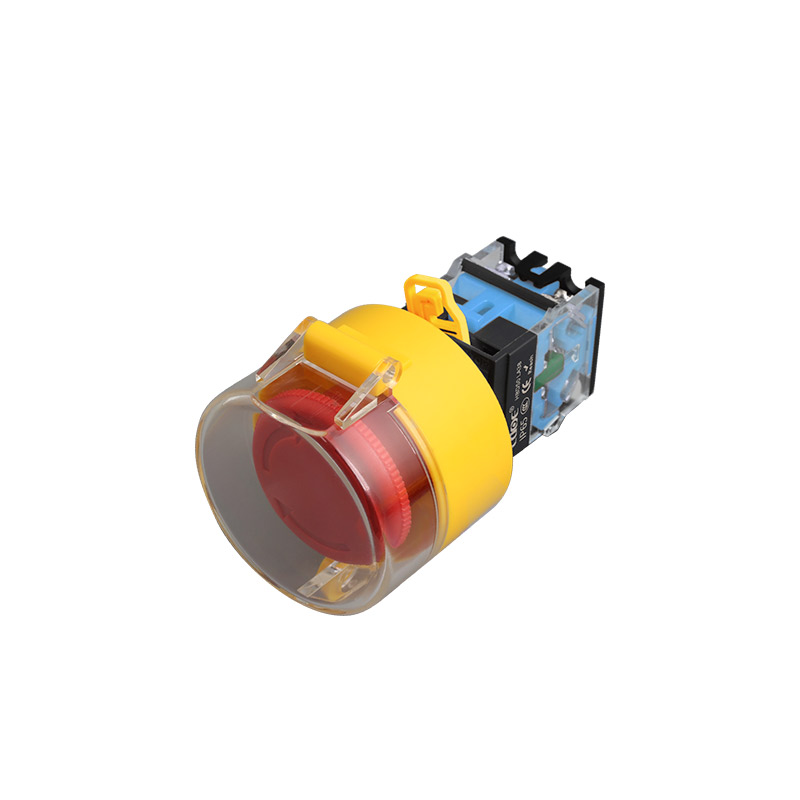

5. Emergency stop button with protective cover

Features: Combined normally closed and normally open contacts, 10A 660V rated current, multiple head designs available

6. Emergency stop switch button box

Equipment: Warning ring and button box are available together as a set.

Above is a brief overview of some emergency stop switch series from the CDOE brand. We also offer additional models and customization services to meet your requirements in various scenarios. For more product information or selection advice, please contact our contact us professional customer service team. We are committed to providing you with personalized premium service.