1. Series Introduction

AGQ series metal push button switches have super metal texture and smooth appearance design.Made of silver contact solder feet, built-in resistance, using bright LED lamp beads, equipped with accessories such as waterproof rubber rings.Optional voltage (6V, 12V, 24V, 48V, 220V….),Different size diameters: 16mm, 19mm, 22mm, 25mm, 30mm.The head (panel mount) is IP67 waterproof. Explosion-proof grade up to IK08. In addition, LED lamp beads: red, green, blue, white, yellow.Switch contact: 1NO1NC or 2NO2NC; switch rating: 5A/250V; Switch type: reset [instantaneous] or self-locking [latching];At the same time, the series also has a selection button (IP40) and an emergency stop button (IP65).

AGQ series is our hot selling product. If you are interested, please contact us!!!

2. Technical parameters

|

Switch rating: |

AC:5A/250V |

|

Ambient temperature: |

-25℃~+65℃ |

|

Contact resistance: |

≤50MΩ |

|

Insulation resistance: |

≥100MΩ |

|

Dielectric strength: |

AC1780V |

|

Mechanical life: |

≥1000,000 times |

|

Electrical life: |

≥50,000 times |

|

Switch structure: |

Single break point snap-action contact |

|

Switch combination: |

1NO1NC,2NO2NC |

|

Surface metal explosion-proof grade: |

IK08 |

|

Protection class: |

IP67 |

|

Operation pressing force: |

3~5N |

|

Operating stroke: |

3mm |

|

Nut torque: |

5~14N |

|

Shell material: |

Nickel plated brass,Stainless steel |

|

Button material: |

Stainless steel |

|

Base material: |

Plastic base |

|

Contact material: |

Silver alloy |

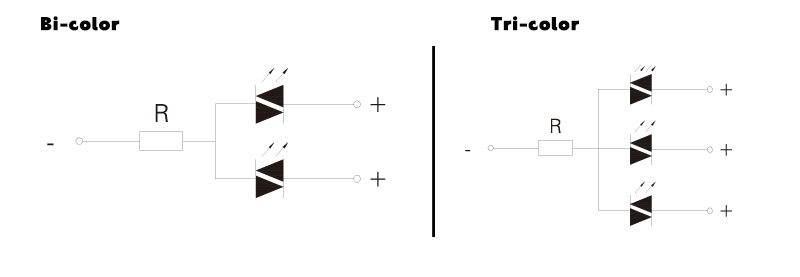

3. LED lamp bead specifications

|

Lamp bead type: |

AC direct universal |

|

Rated voltage: |

1.8V、2.8V、6V、12V、24V、36V、110V、220V |

|

LED color: |

Red,Green,Orange,Blue,White,RG,RB,RGB |

|

Life: |

50000 hours |

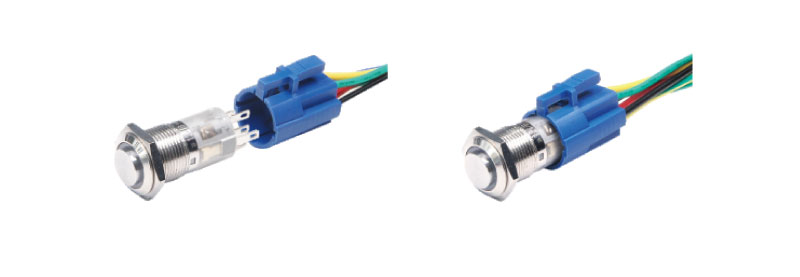

4. Adapter connector

Note: Mating dedicated connectors and buttons are purchased separately.

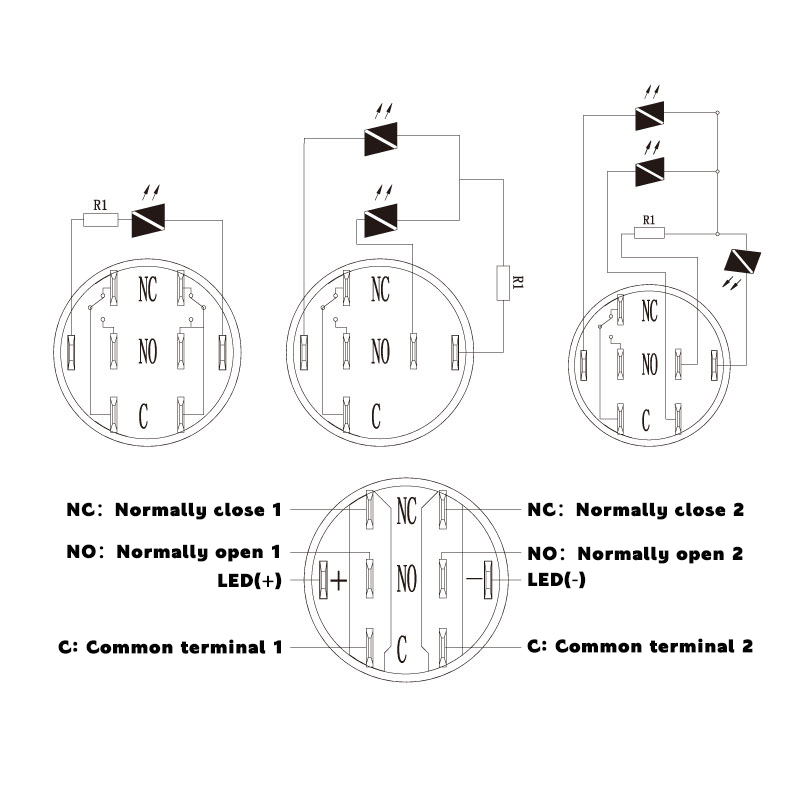

5. Pin Description

NC:Normally open terminal

NO:Normally close terminal

LED(+):Lamp terminal anode

LED(-):Lamp terminal cathode

C:Public

6. Protection and installation instructions

1.Welding precautions: Any incorrect welding operation may cause plastic deformation of the product, poor switch contact, etc. When users use pin-type button switches and signal lights, the phenomenon of product damage due to improper welding often occurs, so please pay attention to the following points when wiring operations:

2. Choose a suitable electric soldering iron to speed up the welding speed. It is recommended to use an electric soldering iron below 30w to complete the soldering within 2 seconds at 320°C.

3. The amount of flux must be appropriate, and the switch pins should face down as much as possible when soldering.

4. Use plug-in terminals as much as possible to avoid welding connections.