In the field of industrial automation and equipment control, push button switches and emergency stop buttons (E-Stop) are two common control components. Although they look similar, their uses and functions are very different. So, which one should you choose in your equipment or production line? This article will deeply analyze the differences between the two, their application scenarios, and how to choose the most suitable button solution for your industrial equipment.

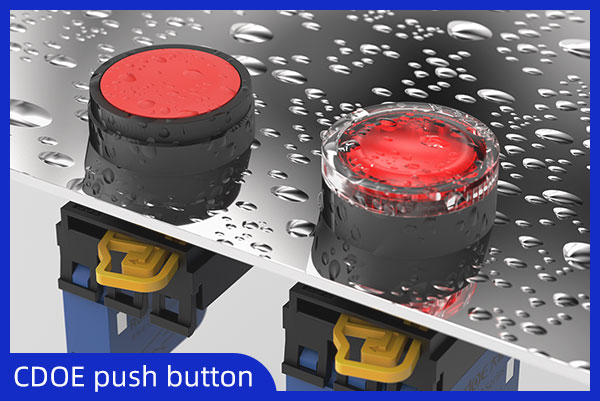

What is a push button switch?

A push button switch is an electric switch used to start, stop or switch the state of a device. It is usually divided into:

- Momentary: The contacts close or open when pressed, and return to the original state after releasing the hand (such as the common start button).

- Latching: After being pressed, the state is maintained and it needs to be pressed again to reset (such as the power switch).

- Button with indicator light: Used to provide visual feedback and display the operating status of the device.

What is function of a push button switch?

A push button switch is a simple control device used to start, stop, or toggle an electrical circuit. When pressed, it temporarily or permanently changes the state of the circuit, allowing current to flow or stopping it.

Main Functions of a Push Button Switch:

- Turning devices ON/OFF (e.g., power switches in industrial machines)

- Mode selection (e.g., switching between manual and automatic modes)

- Resetting circuits (e.g., control panels and alarm systems)

- Signal transmission (e.g., elevator call buttons)

How does a push button switch work?

- Actuator – The part pressed by the user

- Contacts – Electrical terminals that open or close the circuit

- Spring Mechanism – Returns the switch to its original position after release (for momentary switches)

Working Principle:

- Normally Open (NO) Switch: When pressed, the contacts close, allowing current to flow.

- Normally Closed (NC) Switch: When pressed, the contacts open, stopping the current flow.

- Latching Switches: Stay in their new state after pressing until pressed again.

Push button switches are essential in control systems where quick and repeated activation is required.

How many types is the push button switches?

Push button switches come in several types, classified based on function, mechanism, and design.

1. Based on Operation type:

- Momentary Push Button Switch – Returns to its original state after release (e.g., doorbell switch).

- Latching Push Button Switch – Stays in the pressed state until pressed again (e.g., power switch).

2. Based on Contact Type:

- Normally Open (NO) – Circuit is open until the button is pressed.

- Normally Closed (NC) – Circuit is closed until the button is pressed.

- Single Pole Double Throw (SPDT)–Has one input and can switch between two outputs, allowing a single circuit to toggle between two different paths.

- Double Pole Double Throw (DPDT) – Can change between two separate circuits.

3. Based on Features:

- Illuminated Push Button Switch – Includes LED indicators for status display.

- Waterproof Push Button Switch – Designed for harsh environments (e.g., outdoor equipment).

- Anti-vandal Push Button Switch – Made of durable materials for security applications.

Application scenarios of push button switches

- Start/stop control of mechanical equipment

- Industrial automation system

- Elevators, security equipment

- Consumer electronics

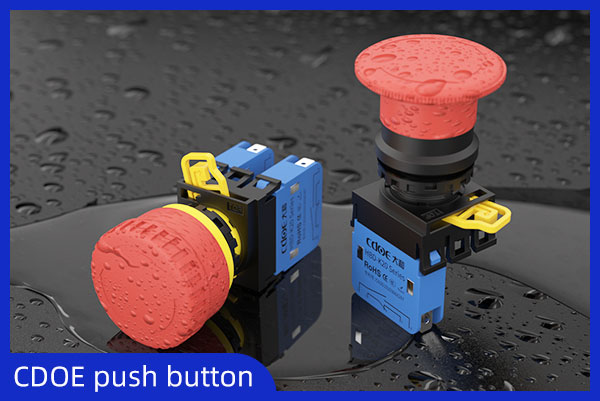

What is an emergency stop button?

An emergency stop button (E-Stop) is a safety device used to immediately halt machinery or equipment in case of a malfunction, accident, or emergency. It is a critical component in industrial environments to prevent injury and equipment damage. Its features include:

- Conspicuous red design with yellow background (in compliance with international safety standard ISO 13850).

- Self-locking mechanism: remains locked after being pressed and must be manually rotated or pulled up to reset.

- Positive Break mechanism ensures that contacts are completely separated to prevent malfunctions.

What is function of an emergency stop button switch?

- Instantly stops machine operations

- Prevents accidents and injuries

- Protects equipment from damage

- Ensures compliance with safety regulations (ISO 13850, IEC 60947-5-5)

Emergency stop buttons are widely used in factories, robotics, conveyors, elevators, and hazardous work environments.

How does an emergency stop button switch work?

An emergency stop button works by breaking the electrical circuit when pressed, cutting off power to the machine.

Working Mechanism:

- Self-Locking Mechanism: When pressed, the button stays locked in the OFF position.

- Force-Disconnect Contacts: Designed to ensure safety by physically separating the contacts.

- Manual Reset Required: The button must be twisted or pulled to reset and allow the machine to restart.

Types of Activation:

- Push-to-Lock, Twist-to-Reset (most common)

- Push-to-Lock, Pull-to-Reset

- Key Reset (requires a key for unlocking, for restricted access)

Emergency stop buttons play a key role in workplace safety, ensuring quick response during emergencies.

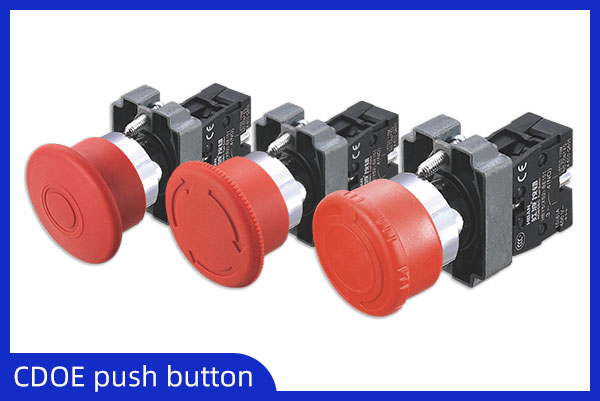

How many types is the emergency stop switch?

Emergency stop switches (E-Stops) are categorized based on their reset mechanism and design specifications.

1. Based on Reset Mechanism:

- Twist Release E-Stop: The button is reset by twisting it back to its original position.

- Pull Release E-Stop: The button is reset by pulling it outward.

- Key Release E-Stop: Resetting requires a special key, ensuring only authorized personnel can restart the system.

2. Based on Design:

- Mushroom Head E-Stop: Large, round button for easy pressing in emergencies.

- Flush Mounted E-Stop: Installed flush with the surface to prevent accidental activation.

- Enclosed E-Stop: Comes with a protective cover to avoid unintentional pressing.

Choosing the right type of emergency stop button depends on industry requirements, safety regulations, and environmental conditions.

Application scenarios of emergency stop buttons

- Mechanical equipment safety protection

- Production line emergency shutdown control

- Elevators, safety doors, robotic systems

- Medical equipment and laboratory equipment

Push Button Switch vs. Emergency Stop Button

| Comparison Items | Push button switch | Emergency Stop Button |

|---|---|---|

| Key Features | Control device on/off, mode switching | Stop equipment operation to ensure safety |

| color | Common colors: red, green, blue, white, yellow, etc. | Standard red with yellow base |

| Operation type | Momentary or Latching | Latching |

| Safety Standards | No strict safety requirements | Must comply with standards such as ISO 13850, EN 60947-5-5, etc. |

| Applicable environment | General control/operation | Equipment requiring emergency safety protection |

| Application Industry | Electronics, home appliances, machinery, security, etc. | Industrial automation, production lines, medical treatment, transportation, etc. |

How to choose the right push button for your industrial application?

1. When to choose push button switch?

- Need to control the device on and off for daily use.

- Need to switch between different modes (such as start/stop).

- Suitable for general operation, not emergency situations.

2. When to choose Emergency Stop Button?

- There are safety hazards during the operation of the equipment.

- The power supply needs to be quickly cut off in an emergency.

- Applicable to high-risk environments such as industrial production lines and automation equipment.

Conclusion:

Both push button switches and emergency stop buttons play essential roles in industrial automation and control systems. While push buttons are used for normal operations, emergency stop buttons are critical for safety.Looking for high-quality push button and emergency stop switches? Contact us for customized solutions that meet international safety standards!